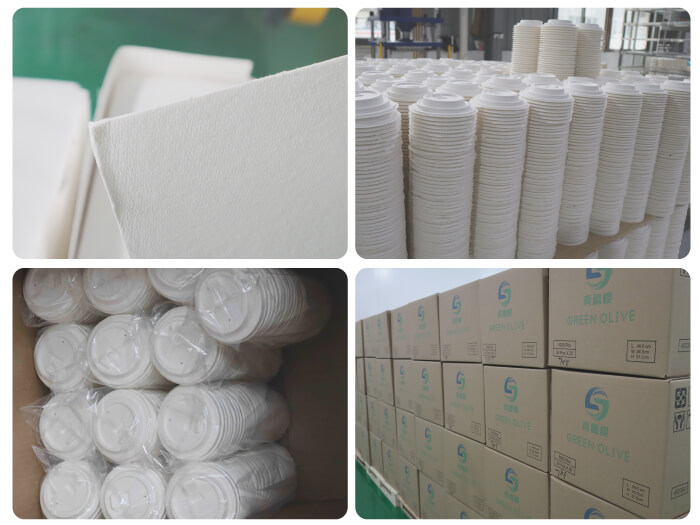

GREENOLIVE production base was designed and built according to industry hygiene and safety standards and in accordance with the requirements of ISO9001 & ISO 14001 standards for the production of food packaging. GREENOLIVE holds the compostability certification in the sector-the most widely used compostability standards European EN13432 and the American ASTM D6400.

Across an area of 10,000 ㎡ at phase 1 factory. There is the location of warehouses and office space. With an annual production volume in excess of 5000 tons at the first phase factory, we are capable of handling vast quantities of production. Our expected capacity is 40,000 tons per year at the second phase after put into production in 2022. If you are looking for a company that can handle biodegradable packaging in massive quantities, then you can rely upon our team.

With advanced scientific formula and cutting edge automatic equipment and technique, GREENOLIVE made from natural plant fibers pulp like sugarcane bagasse and bamboo pulp, which are tree free, carbon neutral, environmental friendly, compostable and biodegradable. It's a new environmental product with full of potential considering global plastic restriction under scenarios of climate change and plastic pollution.

● Plastic-free: 100% made from plant biomass such as sugarcane bagasse and bamboo pulp

● Biodegradable: can be 100% degradable under natural conditions in 90-100 days. Works just as well for landfills too.

● Waterproof & Oil Proof

● Microwave & Refrigerator safe: Perfectly suited for serving hot and cold food

All raw materials are sourced by importing from responsible and reliable suppliers in Thailand to make sure safety and quality. GREENOLIVE has implemented a rigid quality control scheme in production process; ensure the overall conformity rate of final products can achieve 95%+.

Plus In order to provide tailor made molds according to customer's requirements and ensure swift turnaround in mold modification, the company has built our in-house molding workshop with senior tooling engineers and cutting edge tooling equipment to control quality from the source and improve efficiency. Offering our customers professional & better OEM & ODM service for biodegradable package.

if you have any questions, you can click the button below to contact us.

Contact Us

Tel: +0086 0769 86307376

Whatsapp: +86 181 5946 0878

Email: [email protected]

Factory Add: No. 2, Jindong 2nd Rd., Fengcheng Street, Yongding District, Longyan, Fujian, 364100,China

Headquarters: Room No. 2815, 28F, Wanda Center, Dongcheng Dist., Dongguan, Guangdong, 523000 P.R.China