![]() Dec 22 2022

Dec 22 2022

![]()

Disposable tableware has brought convenience to people's lives, especially with the development of the food delivery industry, the number of disposable tableware consumed by people has surged. my country's online food delivery platforms are mainly Meituan and Ele. me. According to the statistics of the amount of disposable tableware consumed by environmental protection organizations, an average of 3.27 disposable plastic tableware will be consumed per order of food delivery, and the platform will consume nearly 80 million per day. . From a global perspective, the world consumes about 16 billion disposable coffee cups every year and discards 1 billion plastic straws every day. Such a huge consumption makes about 8 million tons of plastic waste flow into the ocean every year. It is conservatively estimated that these plastic wastes also take 450 years to degrade.

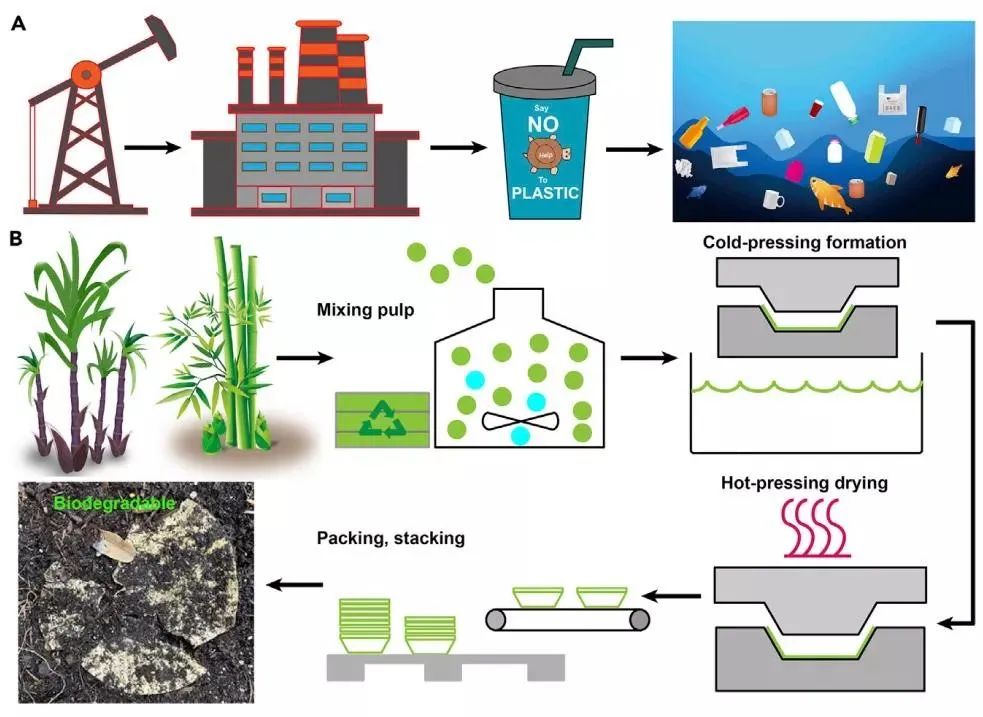

(A) Schematic diagram of the manufacture of disposable tableware from petroleum; (B) Schematic diagram of the production of biodegradable tableware using bagasse and bamboo fiber

Zhu Hongli's research group at Northeastern University in the United States blended short bagasse fibers with long bamboo fibers. The two fibers were physically entangled to form a highly intertwined network structure and then prepared disposable tableware through cold pressing and hot pressing drying processes. It can completely replace plastic and traditional paper tableware.

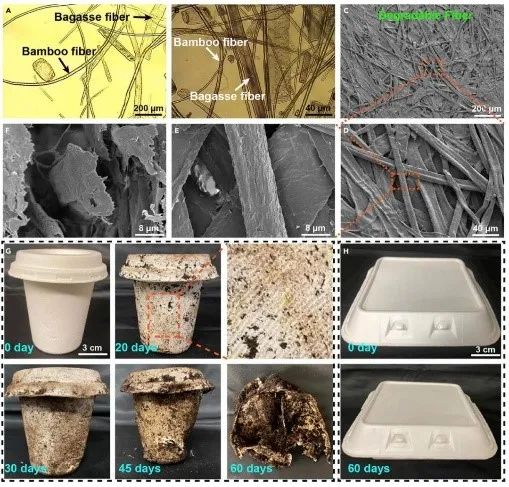

Through the electron microscope, the researchers found that the lignin in the hot-pressed fibers melted and the hydrogen bonds between the celluloses made the fibers tightly bonded together to form a 3D network, which improved the water resistance and strength of the product.

(A-B) Optical micrographs of hybrid fiber at different magnifications; (C-F) SEM images of tableware surface at different magnifications; (G) Biodegradation performance of hybrid fiber tableware compared with plastic tableware (H)

To study the biodegradability of tableware, the researchers buried them in the soil and periodically checked for changes in shape and weight. It was found that after 20 days of burying, yellow fungus appeared on the surface of the tableware, and it began to deform after 30-45 days, completely lost its shape, and gradually disappeared after 60 days. Moreover, the weight of the cup dropped from 7.99 g to 4.18 g after 60 days, almost half of the degradation. In contrast, the appearance and shape of the comparison polystyrene (PS) plastic tableware did not change after 60 days of embedding.

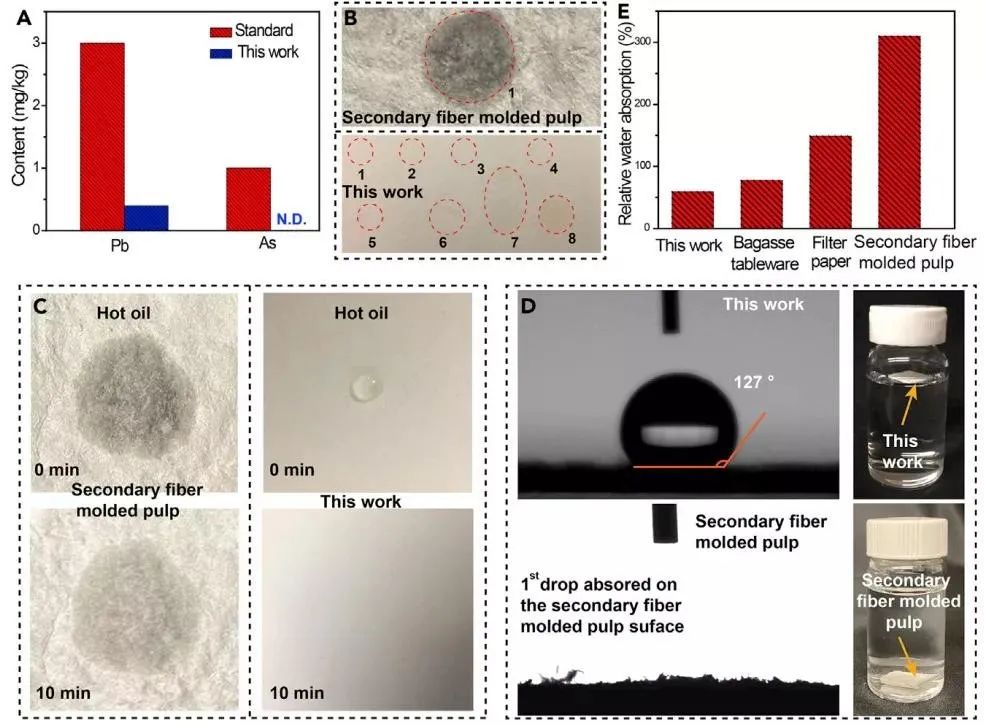

Since it is used as tableware, its safety must be guaranteed first, especially since the content of heavy metals, such as Pb and As, cannot exceed the standard. According to European food contact material regulation (EC) No. 1935/2004 and GB 4806.8-2016 Chinese national food safety standard (food contact paper and paperboard materials and their products), the content of Pb and As should be less than 3.0 mg/kg respectively and 1.0 mg/kg. The researchers used inductively coupled plasma emission spectrometry (ICP-OES) to analyze the Pb and As content in the mixed fiber tableware, and found that the Pb content was 0.3633 mg/kg, only 1/8 of the standard value, and no As was detected. exist.

As tableware, oil resistance and water resistance are also very critical. The contact angle of mixed fiber tableware to the water reaches 127°, the contact angle of secondary fiber molding pulp SFMP and filter paper to water is 0°, and the contact angle of commercial bagasse tableware is 93°. The mixed fiber material shows excellent hydrophobicity. Not only that, the water absorption of the mixed fiber tableware is only 59.4%, while the commercially available bagasse tableware is 77.5%, the filter paper is 149.2%, and the SFMP reaches 310%. Such low water absorption is due to the high hydrophobicity and dense structure of the mixed fiber. of.

In order to evaluate the oil resistance of tableware, the researchers conducted an analysis according to the standard of 559 pm-96 of the Technical Association of Pulp and Paper Industry (TAPPI) and found that the oil resistance of mixed fiber tableware was 6, which was much higher than that of SFMP (1), commercial bagasse Tableware (grade 4) and filter paper (grade 1), exhibiting excellent oil resistance.

The researchers compared the mechanical properties of the mixed fiber and PS tableware and found that the tensile strength was 35.0 MPa, more than double that of the PS plastic cup (15.6 MPa), and Young's modulus was 3.25 GPa, much higher than the 1.40 of the PS plastic cup. GPA. A 7.9-gram mixed fiber paper cup can bear a weight of 3kg and still maintain its shape. This load is 380 times its own weight.

The researchers estimated the amount of carbon dioxide emitted during the production of mixed fiber tableware. It is reported that the carbon dioxide emission from producing 1 kg of expanded PS plastic is 7.36 kg; according to the statistics of the European Carton Board Manufacturers Association (Pro-Carton), the emission of 1 kg of molded pulp products is 0.22 kg. Therefore, the CO2 emission of molded mixed fiber tableware is 97% lower than PS tableware and 65% lower than conventional disposable paper and PLA plastic tableware.

In addition to good performance, materials must be cheap to be king. By comparing the statistics of the Plastics Insight-Market Intelligence website, the researchers found that the cost of mixed fiber tableware is US$2333/ton, only half of PLA ($4750/ton), and close to PS tableware ($2177/ton).

PRODUCT CATEGORIES

![]() You May Also Like

You May Also Like

Custom Biodegradable Bagasse Pulp Cuplids, Coffee Paper Cup And Lids

80mm Bagasse paper lid, dome shape, natural brown

Wholesale Biodegradable Disposable Bagasse Salad Rice Fruit Bowl

7 x 5 inch Rectangle bagasse clamshell, white

Corrugated pulp disposable 4 cup holder tray takeaway carrier

90mm natural brown sugarcane pulp sip lid, round design

90mm White sugarcane pulp sip lid, round design