![]() Apr 09 2022

Apr 09 2022

![]()

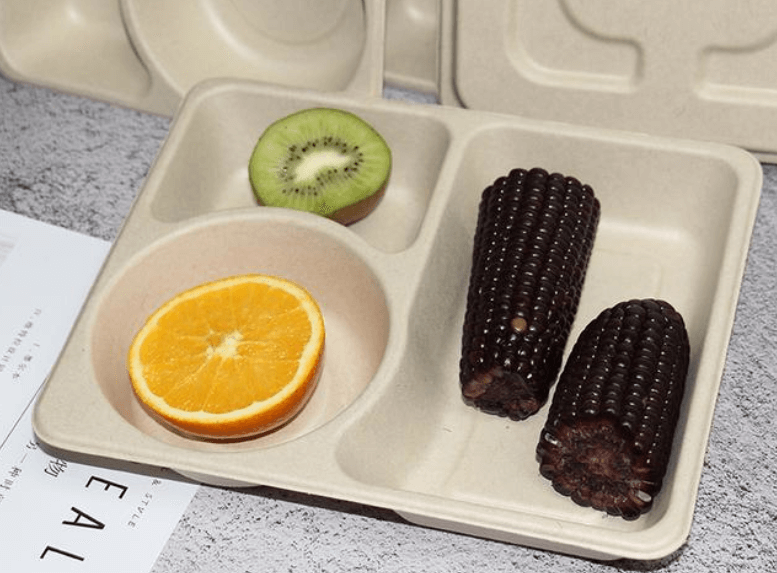

1. What are the raw material ingredients and their respective ratios used in the disposable degradable lunch box?

Conventional lunch boxes are generally based on 70%-90% sugarcane fiber + 10%-30% bamboo pulp fiber. Different tableware will also adjust different fiber ratios according to the shape, angle, hardness and stiffness of the product. Of course, wheat straw, wheat straw, reed and other plant fibers will be added as needed. All of them are made of plant fibers, and no chemical materials such as PP and PET are added.

2. How can the disposable pulp lunch box achieve the waterproof and oil-proof effect?

Pulp molded lunch boxes will be added with certain food-grade additives, general waterproofing agent: 1.0%-2.5%, oil-repellent agent: 0.5%-0.8%, to achieve the effect of waterproof and oil-proof. The test is generally 100 ℃ water, 120 ℃ oil, the test time is 30 minutes; special requirements can be done to extend the oil temperature test time.

3. Do degradable disposable tableware products contain fluorine?

At present, most of the oil repellents in vegetable fiber tableware on the market are fluorine-containing, and tableware that is waterproof and not oil-proof is fluorine-free.

If the degradable tableware is required to be fluorine-free and waterproof and oil-proof, a better alternative at present is film coating. PBAT is currently the most widely used and used composite material in pulp molded environmentally friendly tableware.

The film-coated product can keep better heat preservation, reduce the heat dissipation through the pores of the molded product, and at the same time reduce the stickiness of food such as rice and dumplings, which can greatly reduce the use of water repellent and oil repellent.

4. How long does it take for environmentally friendly pulp tableware to degrade completely?

In the absence of any industrial decomposing machine, it takes about 45-90 days for the pulp molded environmentally friendly tableware to be completely decomposed in the natural state of the landfill.

After degradation, 82% of the ingredients are organic matter, which can be used as fertilizer for land use.

5. Can disposable pulp tableware be microwaved and refrigerated? What temperature can it reach?

The degradable pulp lunch box can be microwaved and oven baked without harmful chemicals, and the maximum temperature can reach 220℃.

It can support refrigerator freezing and refrigeration, and freezing can reach minus 18 ℃.

6. What type of product quality inspection standards does the pulp molded lunch box meet?

The fully biodegradable plant fiber lunch box conforms to the national quality inspection standards of "Pulp Moulded Tableware", the United States Food and Drug Administration (FDA), the German New Food and Dietary Goods Act (LFGB), and other international standardized inspection standards.

7. Can the logo be printed on the biodegradable lunch box?

Logos can be printed. The printed products are mostly the perimeter, bottom or top of the lunch box products. Products such as cups and bowls are mostly printed on the outside of the product, and surface printing is required. According to the printing equipment, it is divided into screen printing, pad printing and laser laser printing (jet printing).

Printing products will increase product costs accordingly.

8. Have the raw materials used in the white degradable lunch box been bleached? What bleach to use?

The unbleached vegetable fiber pulp has a yellow color and hard fibers because it contains a small amount of lignin and colored impurities. The semi-bleached pulp contains a large amount of pentose polysaccharides, and the color is light yellow, commonly known as the true color. The fibers of bleached pulp are white, pure and soft, but due to the bleaching treatment, the fiber strength is lower than that of unbleached pulp. Bleach is generally bleached with hydrogen peroxide, not chlorine bleach!

PRODUCT CATEGORIES

![]() You May Also Like

You May Also Like

Custom Biodegradable Bagasse Pulp Cuplids, Coffee Paper Cup And Lids

80mm Bagasse paper lid, dome shape, natural brown

Wholesale Biodegradable Disposable Bagasse Salad Rice Fruit Bowl

7 x 5 inch Rectangle bagasse clamshell, white

Corrugated pulp disposable 4 cup holder tray takeaway carrier

90mm natural brown sugarcane pulp sip lid, round design

90mm White sugarcane pulp sip lid, round design